Artificial Grass Accessory Polyurethane Adhesive Artificial Grass Installation Glue

| CSA NO: | 9009-54-5 | Other name : | Artificial Grass Installation Glue |

| MF: | C25H42N206 | EINECS NO: | 232-554-6 |

| Place of Origin: | Beijing ,China | Classification: | Double components Adhesives |

| Main Raw Material: | POLLYURETHANE | Usage: | Construction,Artificial Grass Installation |

| Application : | Artificial Grass Installation | Type: | Polyurethane Resin |

| Packing : | A:9 KGS/bucket; B:1kgs/bottle | Mixing Ratio: | A:B 9:1 |

| Open time : | 45 minutes | Solid Content: | 100% |

| Warranty: | 12 months | Curing time: | 4 days |

| Main Number: | Flexibond 8265/8200 | Suitable Temperature: | 0-35 |

Packed with barrel,A= 9KG / barrel; B=1KG/ barrel

Port: Shanghai

1. Preparing Work

a. Substrates Preparation

According to the synthetic grass usage, substrates must be prepared according to current regulations and standards.

b. Synthetic Grass Preparation

Unroll and spread out the synthetic grass for several hours before starting installation to allow internal tension caused by the packaging to be reduced.

c. Adhesive Preparation

The Adhesive should be placed under room temperature in advance. Do not use the adhesive below 0ºC, or higher than 35ºC.

2. Mixing Ratio

Flexibond 8265: Flexibond 8200=9:1 by weight

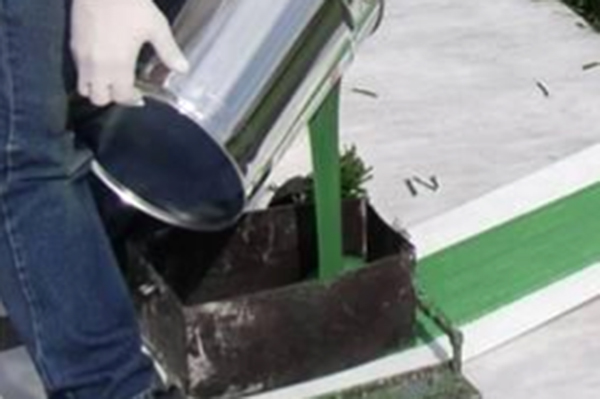

The adhesive is packed as Component A 9kg and Component B 1kg already(Above Picture) . Pour Component B Flexibond 8200 into the barrel containing Component A Flexibond 8265 when use the adhesive. When mixing adhesive of other weight, mixing ratio should be strictly follow 9:1 by weight. Stir with low speed mixer for 2-3 minutes till the adhesive achieves uniform colored paste.

The adhesive open time is around 30 minutes (23ºC). The higher the temperature is, the shorter the open time is; the lower the temperature is, the longer the open time is. Under high temperature, the adhesive should be coated as soon as possible.

1. Preparing Work

a.Substrates Preparation

According to the synthetic grass usage, substrates must be prepared according to current regulations and standards.

b. Synthetic Grass Preparation

Unroll and spread out the synthetic grass for several hours before starting installation to allow internal tension caused by the packaging to be reduced.

c. Adhesive Preparation

The Adhesive should be placed under room temperature in advance. Do not use the adhesive below 0℃, or higher than 35℃.

2. Mixing Ratio

Flexibond 8265: Flexibond 8200=9:1 by weight

The adhesive is packed as Component A 9kg and Component B 1kg already(picture 1) . Pour Component B Flexibond 8200 into the barrel containing Component A Flexibond 8265 when use the adhesive. When mixing adhesive of other weight, mixing ratio should be strictly follow 9:1 by weight. Stir with low speed mixer for 2-3 minutes till the adhesive achieves uniform colored paste.

3. Application time

The adhesive open time is around 30 minutes (23℃). The higher the temperature is, the shorter the open time is; the lower the temperature is, the longer the open time is. Under high temperature, the adhesive should be coated as soon as possible.

4. Adhesive Coated and Synthetic Grass Installation

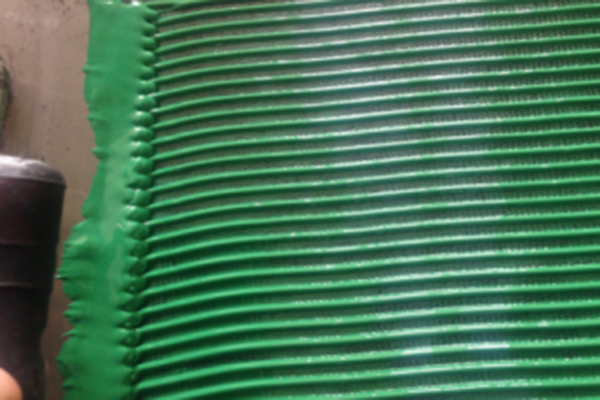

Well mixed adhesive is uniform thixotropic paste which effectively increases its contact area with grass. It is ok to coat the adhesive once.

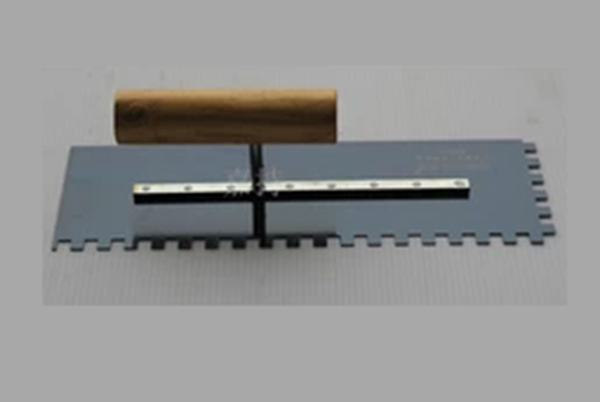

Apply the adhesive onto special jointing strip with tooth trowel (picture 2, 4mm*4mm type) or simple machine (picture 3).

Install the synthetic grass onto the jointing strip before adhesive tack free. In order to achieve good adhesion and evenness, heavy stuff can be putted onto the jointing place. Adhesive open time is around 60 minutes under temperature 23℃. The open time is shortened if temperature rising.

5. Pressing time

Adhesive initially cures in 2 hours under 23℃, sets to light foot traffic in 12 hours, and cures completely in 7 days. The higher the temperature is, the shorter the curing is; the lower the temperature is, the longer the curing is.

6. Consumption

Approximately 0.4kg-0.5kg per meter of 30 cm-wide jointing strip